Thinking of adding metal roofing to your business offerings? Between its high-performance materials, easy installation, and industry-leading warranties, your customers will love getting a new GAF TimberSteel™ premium metal roofing system.

Here’s what you should know about the benefits of selling and working with this metal product.

Start with High-End Materials

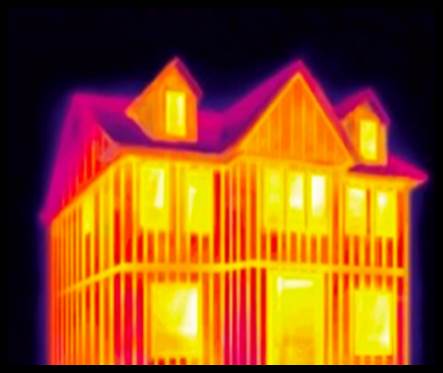

Fabricated from 24-gauge GALVALUME® steel with Class 4 impact resistance, TimberSteel™ roofing systems are especially durable—particularly in parts of the country known for extreme weather events or harsh thermal cycles, says Scott Dawson, GAF Senior CARE Learning and Development Instructor.

“In my area, we’re right in a hail belt. The benefit of that Class 4 material is that, if you get large impacts to the limits of that grading, you’re not going to have catastrophic failures or hail penetrating through to the living space with leakage into the house,” Dawson explains.

The TimberSteel™ system is engineered with premium materials designed to withstand the toughest of conditions, including hail, high winds, and extreme temperatures. And because the product’s self-adhered high-temperature butyl-backed underlayment has some elasticity, it provides a more protective membrane over the roof’s plywood decking than a mechanically attached one would.

Boosting Curb Appeal with the TimberSteel™ System

In addition to its reliable performance, the TimberSteel™ metal roofing system adds an elegant touch to any home. “We now have eight different colors,” says Dawson. “It’s a phenomenal-looking shingle, and it doesn’t look like anything else on the market.”

Eddie Leiss, Director of Marketing and Sales at 5-Star Roofing in Greensboro, North Carolina, encourages contractors to explore the advantages of metal roofs. “As a contractor, I recommend the GAF TimberSteel™ Premium Metal Roofing System because it offers an unmatched combination of superior engineering, strength, and beauty. It stands heads and shoulders above other metal roofs that we’ve worked with,” he explains.

According to Leiss, its design mimics the classic look of a wood shake or dimensional shingle, giving homes a timeless aesthetic with a modern edge. He also appreciates how the finish and color options blend seamlessly with any architectural style. “Homeowners love how it elevates the overall look of their property, delivering elegance and durability in one complete package.”

Save Time with Quick, Easy Installation

The TimberSteel™ metal roofing system can be installed in half the time of an on-site roll formed standing seam metal roof. What’s more, Dawson explains that, unlike many other products, you can use a standard coil nail gun to install the TimberSteel™ system. “You’re not breaking out screw guns and predrilling and trying to set screws all day,” he says. “It’s a much quicker process with a fan-operated or pneumatic coil nailer.”

Dawson recommends residential contractors add heavy-duty turbo shears, like the Malco TSHD, to their toolkits. “They’re designed to cut 18-gauge metals, and although TimberSteel™ field shingles are 24-gauge, they’re doubled at the headlap, so you’re cutting through two layers of 24-gauge,” he explains. “Turbo shears work much better than trying to cut with hand shears all day long.”

Leiss says his crews appreciate how the system is engineered for easy installation, saving time and ensuring a precise fit. “It’s incredibly well-designed, fitting together seamlessly. It’s also lighter than other metal roofs while still delivering outstanding strength and durability,” he notes. “My crews love that they can install the roof system using the same nail guns they’ve always used. They like how the size and weight of the shingles make them easier to control on the roof.”

Dawson estimates six to eight crew members can install the TimberSteel™ system. He suggests residential contractors take advantage of GAF jobsite trainings where teams can get tips for smooth installation. “It’s a good idea to have anybody who’s going to be involved in this product moving forward—whether they’re sales or project managers or owners—come out and learn this new process and how to work with these new materials.”

Logston graduated from the University of Colorado Boulder with a degree in Environmental Studies before pursuing her MFA in Creative Writing at the Iowa Writers’ Workshop. Logston’s work often draws inspiration from her outdoor experiences and her commitment to environmental causes.